The new painting system

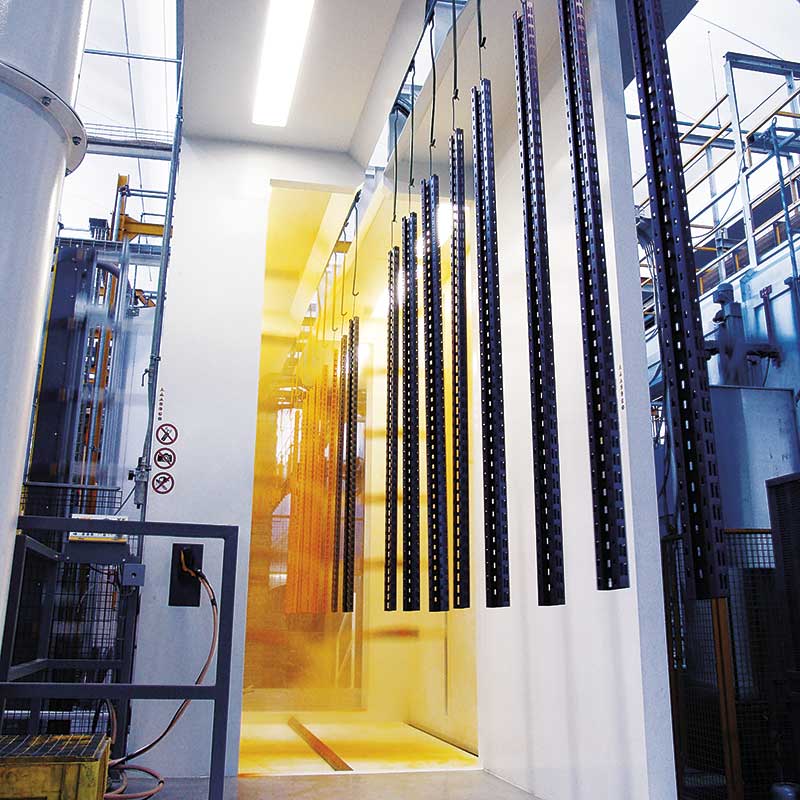

The Wagner Supercenter cabin

The Wagner Supercenter cabin features a quick colour change system, and is the new powder coating system that marked the start of Fami’s new-generation of highly automated industrial processes. Our choice is based on the attention we pay to both the quality of the painting of our products and to the strong feeling of respect for our territory, aware that the new process can combine the optimization of production costs with a real eco-environmental commitment.

The new equipment is an easy to use cutting-edge system; it is a modern workstation that guarantees the best results when painting our industrial furnishings, optimizing the colour change and recovery of excess powder, offering a reliable and top-quality coating.

The fast and automated colour change procedure is the key point of the new cabin: in just eight minutes, the “SuperCenter” for colour change, managed by just two operators, changes the colour and cleans the guns, pipes, intake ducts, recovery cyclone, powder tank and lid.

Another turning point: powder recovery, at all times. The excess colour is sucked, filtered and returned to the tank where it is recycled together with other powder residues, reducing the colour loss over the cycle to about 2/3%. With the new Wagner Supercenter powder plant, built using antistatic material, we paint products of all kinds, up to a maximum height of 2,700 mm and a width of 1,000 mm. The standard working speed is 1.50 m/min and the control logic is fully PLC-controlled via a Backhoff operator panel.

The system consists of 2 motorized reciprocators with encoders that drive 12 automatic guns, an automatic positioner with a motorized 90° head gun and two manual guns positioned at the entrance and exit of the cabin. The procedure uses a detection system for the piece to be painted (through Scan barrier) which, after examining its size and type, establishes the following steps: the precise position of the reciprocators, the exact distance of the guns from the product, and the amount of colour to be sprayed. The location of the piece allows the equipment to define the precise point where the guns must begin to spray the colour and the sensitive points where spraying must be stopped, such as the frames or the edges of the doors. In addition, a depth reader adjusts the position of the guns at the right distance from the piece to ensure it is evenly coated.

In line with the growth objectives of the current industrial plan, the activation of this plant by Fami confirms the company’s desire to become the leader in the sector, demonstrates its intention to invest in the future, as well as its constant commitment to develop and adopt technological solutions that allow obtaining high operating returns, greatly reducing waste and pollution.